At Hispec, quality isn’t just a checkpoint, it’s the cornerstone of our success

Our comprehensive quality assurance programs combine stringent testing procedures, thorough auditing and strategic manufacturing partnerships to deliver products that consistently exceed industry standards.

Quality Management

Systems

We maintain robust quality management systems

certified to:

- ISO 9001:2015 Quality Management.

- ISO 14001 Environmental Management.

- Industry-specific quality standards.

Customer

Assurance

Our quality assurance program provides customers with:

- Comprehensive warranty support.

- Detailed technical documentation.

- Responsive customer service.

- Regular quality performance updates.

The Hispec Beyond

Audit Programme

Our pioneering Beyond Audit Programme ensures

excellence throughout our supply chain:

Key Programme Elements

- Regular supplier assessment and validation.

- On-site quality inspections by dedicated teams.

- Real-time production monitoring systems.

- Advanced testing protocols at each stage.

- Continuous improvement initiatives.

Looking

Ahead

We continuously evolve our quality assurance

processes to:

- Incorporate new technologies.

- Thorough manufacturing plant audits.

- Adapt to changing standards.

- Respond to customer feedback.

- Enhance product performance.

- Maintain industry leadership.

Industry Education and Nurturing Young Learner Development

Our partnership with BSI (British Standards Institution) ensures rigorous independent verification of our products:

Independent verification of all safety critical components

Real world performance testing under varied conditions

Products individually tested at least twice

Pre production samples thoroughly tested before order acceptance

Continuous compliance monitoring

The Phases Of Testing

Standards and

Certifications

- BS EN Standards compliance across our product range.

- CE and UKCA marking validation.

- Regular certification updates to meet evolving standards.

Our Strategic

Partnership

Our state of the art manufacturing facilities in China represent a strategic choice that enables us to combine advanced technology with rigorous quality control:

Advanced Manufacturing Capabilities

- Cutting edge production lines with several phases of

quality control. - Clean room environments for sensitive components.

- Advanced testing and validation equipment.

- Modern assembly processes ensuring consistent quality.

- Sophisticated quality management systems.

People and

Expertise INVESTMENT

Our commitment to quality is backed by significant people & expertise investments:

- Skilled UK quality control teams.

- Regular staff training programs.

- Technical expertise development.

- Sales aftercare and technical support line.

- Dedicated Regional Specification Manager and Key

Account Manager.

Technology and

Infrastructure INVESTMENT

Our commitment to quality is backed by significant tech & infrastructure investments:

- State of the art testing equipment

- Modern production facilities

- Advanced quality control systems

- Automated inspection technology

Quality Control

Infrastructure

- Advanced testing at each production stage.

- Real time monitoring and reporting systems.

- Comprehensive pre shipment inspection protocols.

Partner

with Quality

When you choose Hispec, you’re choosing a partner committed to:

- Rigorous testing and certification.

- Comprehensive quality control.

- Strategic manufacturing partnerships.

- Continuous improvement.

- Customer-focused innovation.

Our Quality

Assurance Journey

Each product goes through a comprehensive quality journey:

- Design Phase

- Rigorous product development from our UK team

- Prototype testing

- Performance validation

- Safety compliance verification

- Production Phase

- Material quality checks

- In process quality control

- Statistical process control

- Production line audits

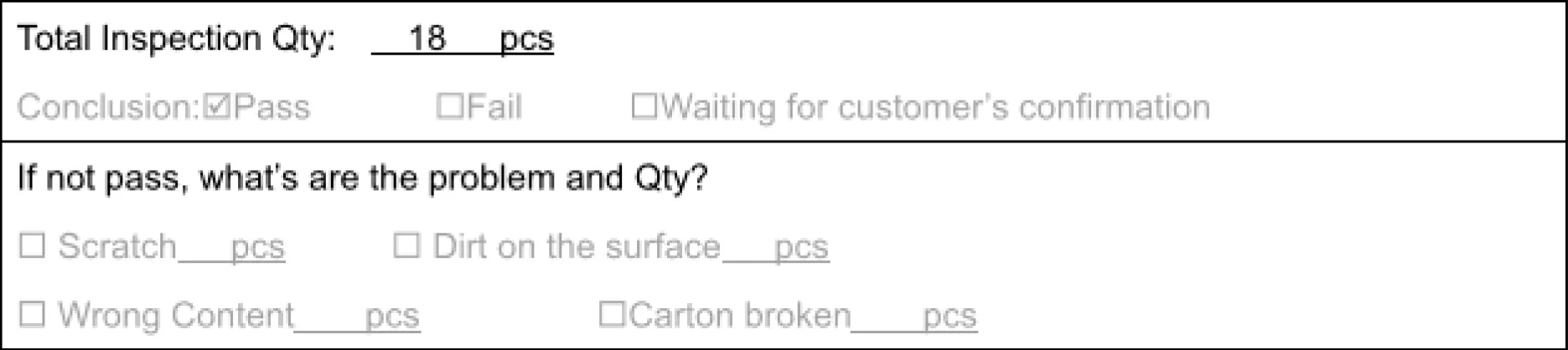

- Pre-Shipment

- Individual product testing

- Documentation verification

- Performance validation

- Packaging quality checks

- Post-Delivery

- Market performance monitoring

- Customer feedback analysis

- Continuous improvement implementation

- Regular product reviews

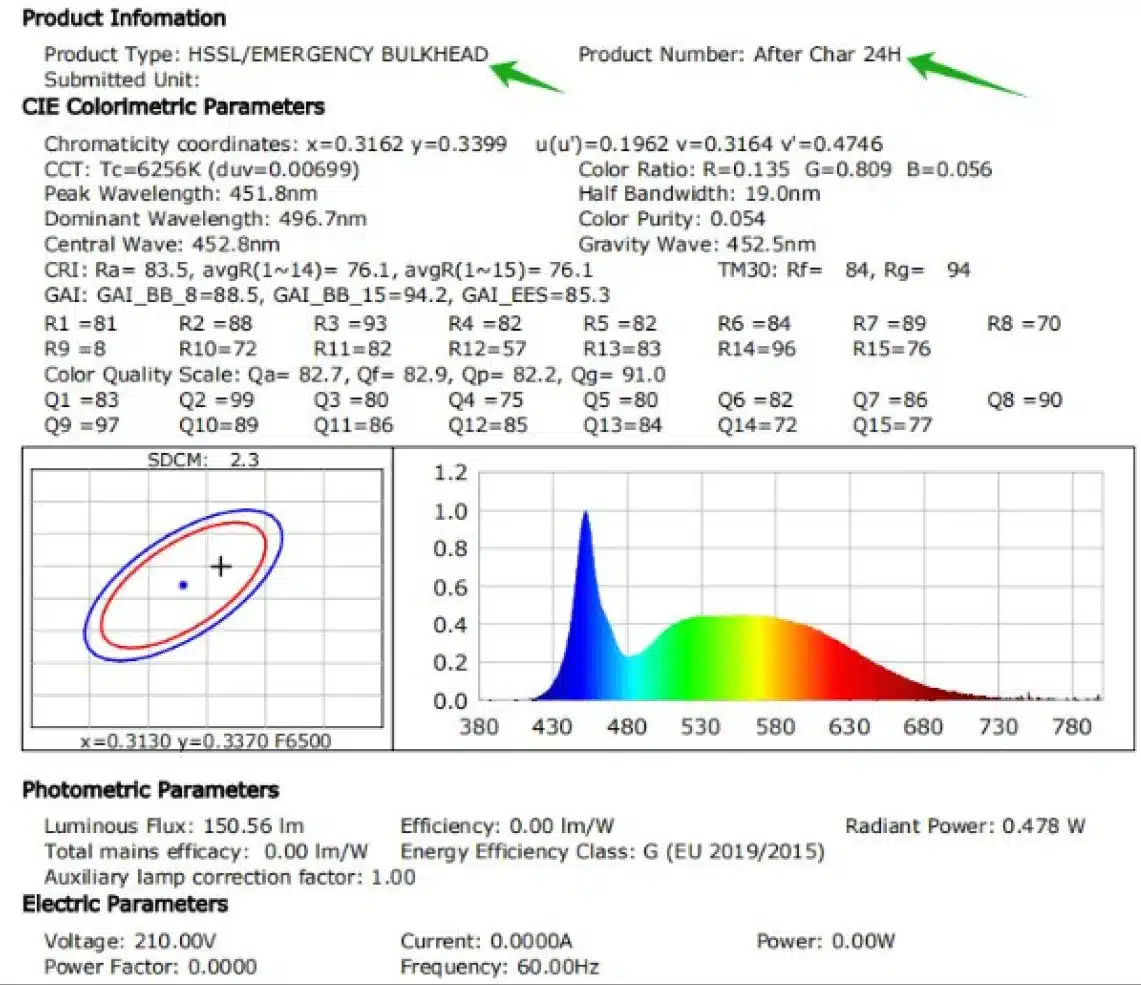

Lighting Quality Testing Procedures

Comprehensive testing protocols ensuring safety, performance, and reliability.

Product Safety

& Standards

- Compliance with EN IEC 60598-1 Luminaires:

General requirements and tests. - Product-specific testing per EN IEC 60598-2

Luminaires: Particular requirements. - Third-party verification and certification.

Performance

Testing

- Component soak testing for reliability and rated lifetime.

- Photometric testing for lumen output and color

temperature (CCTk). - Emergency lighting 3-hour duration testing.

- Ingress Protection (IP) testing.

Electrical

Safety

- Hi-Pot testing: Also known as a dielectric withstand

test. It’s one of many types of electrical testing that is

typically performed on cable and wire harnesses. - Insulation resistance verification.

- Ground resistance checks.

- Leakage current measurement.

- Cable pull testing (60N force, 25 repetitions).

Quality

Assurance

- Pre-shipment inspection by specialist lighting auditors.

- Battery manufacturing date documentation.

- Installation date labeling system.

- Sustainable packaging verification.

- Product marking and safety packaging checks.

Soak Testing Products

- Product Safety, checked against EN IEC 60598-1 Luminaires : General requirements and tests &

EN IEC 60598-2-## Luminaires: Particular requirements, which differ depending on product type/application. - Product Soak Test, components are all conditioned to ensure correct operation and to avoid any faulty components

when put under electrical load. Crucial for reliability and rated lifetime.

Electrical Safety Testing

Including Hi-Pot, Insulation Resistance, Ground Resistance and Leakage Current tests.

Ingress Protection (IP) Testing

Emergency Products

Tested to ensure full rated duration of 3 hours is achieved, for safe illumination when needed.

Battery manufacturing

Dates are printed along with space/label for a contractor to mark commissioning/install date. Vital for when checking battery service life.

Pull testS

Pull test conducted on any relevant input cables, Minimum 60N force applied 25 Times.

Photometric testing

Photometric (Light Output) testing. Confirming the Lumens and Colour Temperature (CCTk) are within specifications.

Product Packaging

Using sustainable materials wherever possible. To ensure product is correctly marked and safety packaged to ensure it arrives in best condition.

HSSL/FESTOON-22M

Most Of Hispec’s Products Are Designed And Developed In The Uk And Manufactured In China

Like many suppliers in our industry, Hispec partners with select factories in China to produce our electrical products.

This collaboration is driven by two primary factors: manufacturing expertise and cost efficiency.

Regional

Specialisation

Regions in China specialise in specific goods:

- Fujian Province: Sports equipment and clothing.

- Guangdong Province: Electrical products like LED

lighting and smoke detectors. - China has developed concentrated manufacturing expertise through continuous product development and specialised factories.

China has developed concentrated manufacturing expertise through continuous product development and specialised factories.

Cost

Advantages

The cost benefits of manufacturing in China do not come from underpaid labour; rather, they stem from economies of scale. By purchasing components in the hundreds of thousands, manufacturers can achieve significant price reductions. Additionally, China offers access to some of the world’s most efficient manufacturing processes and a skilled workforce, further enhancing efficiency and lowering costs for businesses meaning we can pass savings on to our customers.

Industry

Insight

Tim Cook, CEO of Apple, highlighted this issue in a 2020 interview:

“There is a confusion amongst the general public about China. The popular misconception is that companies manufacture in China due to low labour costs—the truth is that China stopped having low labour costs years ago. The reason Apple comes to China is because of the skill and the quantity of skill in one single location.”

Connect With Hispec

For detailed information about our quality assurance processes or to discuss specific requirements, please contact our Quality Assurance team.

"*" indicates required fields